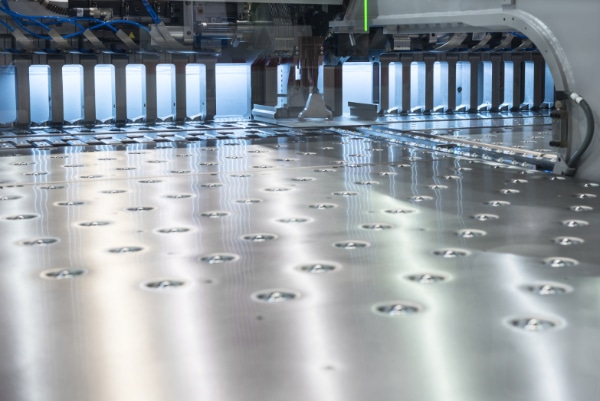

CNC punching can be used for a wide variety of products which makes it a useful service for a variety of different industries. A CNC machine can punch holes in sheets of metal with astounding accuracy. The machines have a tolerance of 0.1mm so you can be sure you’ll always be happy about the outcome. Read on for more information about how CNC punching works.

What Are The Benefits of CNC Punching?

There are many benefits of using CNC punching. As CNC stands for computer numerically controlled, one of the main benefits is increased productivity. Using CNC is a faster and more consistent method for creating products. It also improves the quality of products.

CNC Punching machines have the ability to create features that are formed into the material (such as up forms and down forms, counter syncs and tapping). Key features that protrude from the material include, but in no way excluded to extrusions, embosses, hinges or tabs.

Integrating these features into your part designs can eradicate the need for costly hard tooling that is primarily used in power presses, which can then potentially represent significant cost savings on mid-volume production work.

Using CNC punching will also mean that tools are very durable and will last much longer. Using an automatic punching machine will help to reduce material waste as you are able to nest parts closely together on the sheet material, making it safer and more cost productive for businesses.

For example, if you have a high demand for a particular product with a simple design, CNC punching can take the weight off your shoulders. Instead of hiring a workforce to create these products and deal with constant human error, you have the option of using CNC punching instead and the peace of mind of knowing you can rely on the products to come back exactly as they’re needed.

What Are The Drawbacks of CNC Punching?

Although there are many benefits to CNC punching, there can also be some drawbacks. For instance, if you only need to produce one-off parts, the use of a CNC punching machine is cost-prohibitive. In addition, the time-consuming setup should be considered when ordering parts.

Punching often works out best for parts with simple geometries and already-formed features. More extreme designs and custom orders can take more time and effort.

The Future of CNC Punching Machines

The future of CNC punching stands firmly in the level of complexity these machines can and will deliver. With continuous product variation, CNC punching will be able to deliver products that are as close to flawless as they can be. It is expected that many industries that utilise computer numerical control machines will have an increase in demand over the next ten years and using CNC machinery will help to meet those demands.

Similarly, advanced CNC machines will continue to operate efficiently and accurately. The future of these machines offers far more flexibility, allowing for more custom designs in less time. CNC-supportive processes will also be more freely available, allowing for quick problem-solving and further automation in manufacturing.

Computer-aided manufacturing is the future of manufacturing. Manufacturers who continually adopt these advancements in technology will succeed in this industry.

Here at Wrekin, we are adapting. We use up-to-date technology to provide CNC Punching at a very energy-efficient level towards net zero. Also, we are adapting our sheet metal fabrication processes, for increased efficiency and accuracy, whilst reducing waste.

If you are looking to create high-quality CNC punch products, then look no further.

Here at Wrekin Sheetmetal, we have been open for nearly 20 years, and since, created long-lasting relationships with our customers. We utilise Amada CNC Punches for our CNC punching operations. Contact our friendly team today, who are based in Telford. They are on hand to answer any queries you may have.

How can we help?

With over 17+ years of knowledge and experience, we’re confident we can offer a flexible solution beneficial to both parties, get in touch with us today.